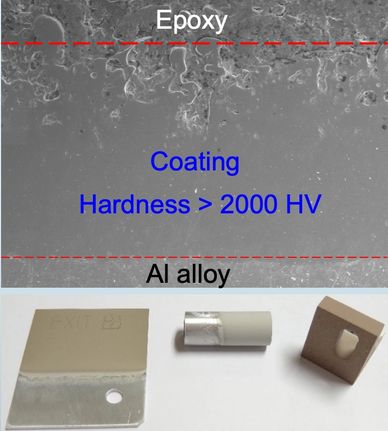

Plasma-in-liquid PROTECTIVE COATING

Plasma-in-liquid coating

Large and non-uniform micro-arcs are the characteristics of the traditional coating process. However, the poorly-controlled large arcs cause:

(1) uneven coating

(2) burning at the edge

(3) excessive heating

Proprietary technology

Our proprietary technology allows only tiny plasma spreading across the sample surface uniformly, to

(1) promote uniform coating growth

(2) reduce damage to the parts

(3) minimize heating

Thus, our coating process is more controllable and energy-efficient.

In-house capability

We have world-class advisors and technical experts on the coating technology. We are committed to deliver excellent products for our clients.

Superior performance

We are constantly pushing the limits of our coating, which represents the best-of-class with:

(1) High hardness (> 2000 HV)

(2) High dielectric breakdown voltage (> 2000 V)

(3) Excellent corrosion-resistance

(4) Conformal coverage along the contour of the 3D parts

Specially developed for semicon

The coating is specially developed to protect critical parts inside the plasma etching chamber for semiconductor manufacturing. With its high tolerance on dielectric breakdown and corrosion, it enables our ALE tools with high reliability and low maintenance costs.

Open for collaboration

Want to find out more on how our coating can transform your products, please feel free to contact us.

Applied Angstrom Technology

Blk 81 Ayer Rajah Crescent, #03-41, Singapore 139967

Contact us: +6562619166

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.